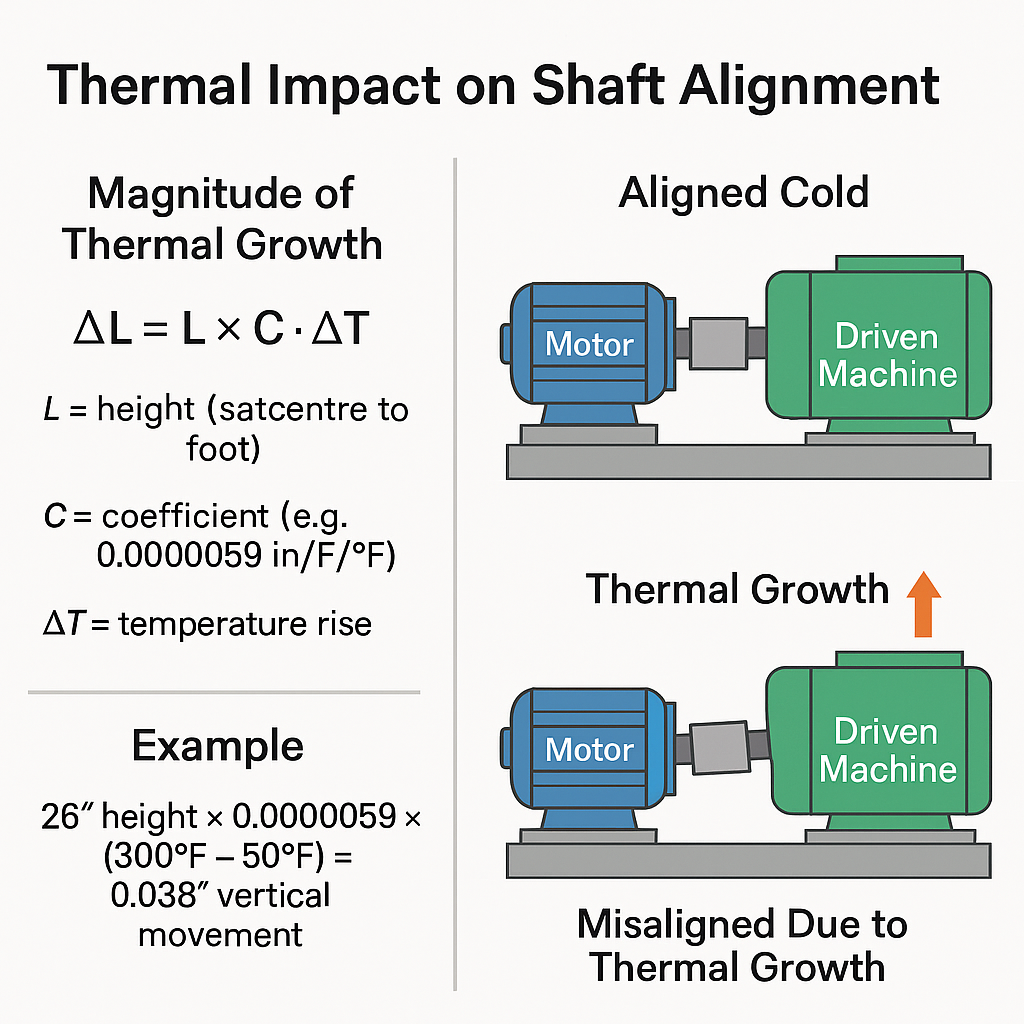

When machines heat up, they grow – and that growth can destroy shaft alignment if not accounted for.

– The Science of Thermal Growth

When rotating equipment operates under load, temperature changes cause the machine casing and shafts to expand. This thermal growth directly affects alignment between coupled machines.

The magnitude of movement can be calculated using the standard formula:

ΔL=L×C×ΔT {Delta L = L times C times Delta T}

Example:

For a motor with a 26″ shaft-center height experiencing a 250°F rise:

26″×0.0000059×250°F≈0.038″26″ \times 0.0000059 \times 250°F \approx 0.038″

That’s nearly 1 mm of vertical movement—enough to cause severe misalignment if left uncorrected.

Practical Example:

A motor aligned “cold” with its driven pump may look perfect during installation. Once the pump reaches operating temperature and one end rises more than the other, the shafts shift, resulting in coupling misalignment and premature wear.

“Hot” Alignment (Cold Targets)

“Hot” Alignment (Cold Targets)Pre-adjust machines by adding shims or offsetting alignment values to compensate for predicted thermal growth. Once the machine heats, shafts settle into proper alignment.

Live Thermal Monitoring

Live Thermal MonitoringAdvanced laser systems (e.g., Easy-Laser, RotAlign Touch, Pruftechnik) measure live shaft movement during warm-up, allowing precise dynamic corrections.

Use Built-In Calculations

Use Built-In CalculationsMany modern alignment tools integrate the ΔL = L × C × ΔT formula, applying thermal growth compensation automatically.

Need thermal growth analysis or precision shaft alignment? Contact THERMOInspect for expert services with advanced laser and infrared diagnostic tools.